Cleanroom Laundry & Sterilisation

Cleanroom laundry is a specialised process for cleaning garments worn in environments that need to be ultra-clean, free of dust, particles, and even microbes.

Why Cleanroom Garment Decontamination Matters

Maintains strict contamination control

Protects sensitive cleanroom environments

Ensures garment particle-free cleanliness

Complies with cleanroom standards

Indispensable for Various Industries

Pharmaceutical

Healthcare

Medical Devices & Life Sciences

Food & Beverage

Semiconductor

Automotive

Watch Our Laundry Process Here

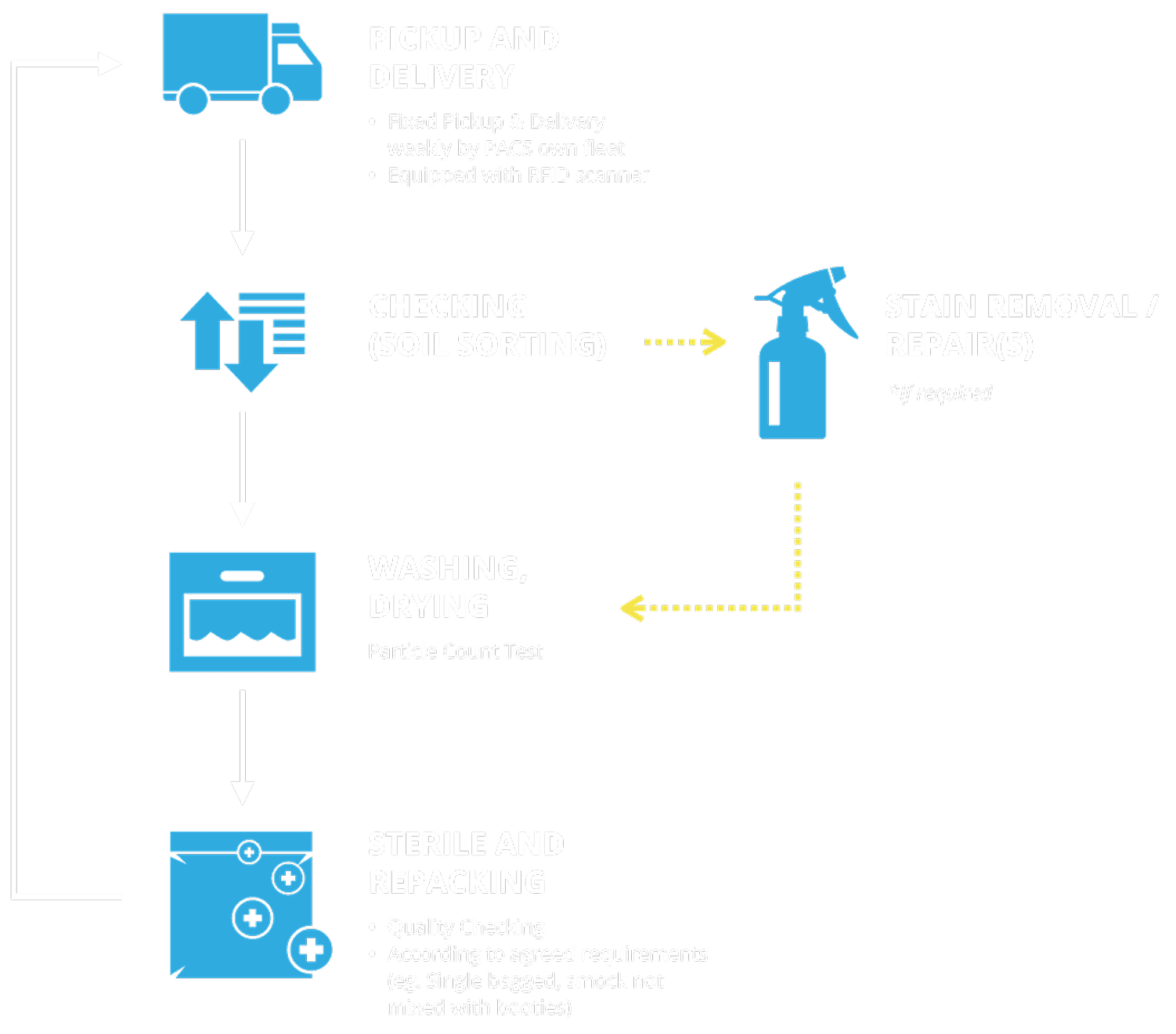

PACS Cleanroom Laundry Cycle

- Caters to various industries such as Pharmaceutical, Electronics manufacturer, food and other types of manufacturing industries

- ISO certified and washed according to ISO 14698-1:2003 standards.

- Garments EOL are validated and compiles to Annex 1.

Garment ESD & Particle Testing

Cleanroom garments are the most important component in ensuring a contamination free environment. We are able to provide various types of tests to ensure garments are compliant in terms of particle and ESD.

Garment Testing

Both Garment ESD & Particle Testing ensure cleanroom garments meet the necessary criteria for:

- Protecting sensitive electronic components/devices from ESD damage.

- Minimising particle contamination within the cleanroom.

- Maintaining a sterile and controlled environment.

Particle count test includes:

- Helmke Drum Test

- ASTM F51

ANSI/ESD Test includes:

- Surface resistivity.

- Sleeve to sleeve resistivity.

RFID & Barcode Tracking

Keeping track of your garments wash cycle, location and even tagging it with staff ID to identify the person wearing it. This is all made possible by implementing an RFID and Barcode solution. Our facility is fitted with high performance RFID readers and systems to capture, tabulate and track inventory for your convenience.

Double-Barrier Protection:

Ensuring Sterile Integrity of The Products

To achieve this, we provide re-packing service in our cleanroom facility and products are then sent for gamma irradiation to achieve full sterile condition.

Sterile packed items are double bagged, marked with batch number and expiry date plus a certified sterile sticker that turns red after being gamma irradiated.